Getting the bathroom faucet installed correctly isn't just about making sure water flows properly. It actually stops expensive water damage and keeps things legal according to local plumbing rules. Most people don't realize this until they've already spent money fixing problems caused by bad installations. According to recent studies from Plumbing Manufacturers International, around one out of every six household water leaks starts right at improperly installed faucets. These issues can really add up too, with repairs costing homeowners approximately seven hundred forty thousand dollars on average when significant structural damage occurs. Faucet installation goes beyond what most consider basic DIY work. Proper setup involves mastering several specific skills that go well beyond simply screwing something onto the wall.

Homeowners often underestimate these precision requirements, resulting in leaks that manifest months later. Mastering these techniques converts installation from a task into a safeguard—eliminating callbacks and preserving water integrity long-term.

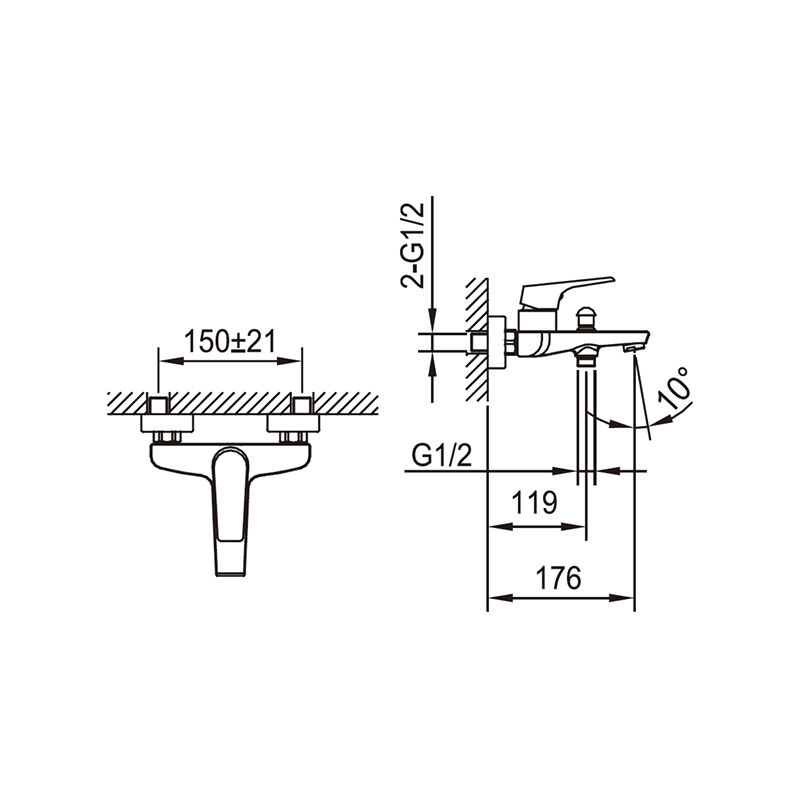

Before grabbing any plumbing tools, there are three things plumbers should absolutely check first. Let's start with thread types NPT versus BSPP. A simple thread gauge will tell the difference, and getting this wrong leads to about two thirds of all leaks within the first few weeks according to Plumbing Standards Journal from last year. Next up, take out those calipers and measure how thick the sink deck actually is. Most standard ones fall between 0.8 and 1.2 inches thick. If it's thinner than that, definitely install a reinforcement plate underneath because otherwise the whole thing might crack under normal use over time. And finally, don't forget to check what kind of valve system we're dealing with here. Ceramic disc valves really need at least 15 pounds per square inch of water pressure to work properly, whereas old school compression valves can handle much less flow. Skip these checks which only take around eight minutes total and suddenly we're looking at cross threaded fittings, cracked basins, or worse yet completely restricted water flow through the fixture.

When securing those mounting nuts, grab a dial type torque wrench and set it between 15 to 25 inch pounds as recommended by ASME standards from 2022. Going over 25 in lbs can actually crack brass tail pieces pretty easily according to Plumbing Manufacturers International stats showing this happens in about 43% of home projects. On the flip side, if someone tightens them below 15 in lbs, there's a good chance vibrations will cause leaks around the 90 day mark. Make sure to apply thread sealant just on the male threads and keep it away from washers. The best approach is tightening in a star pattern so everything compresses evenly. Stop at around 20 in lbs to check how the faucet sits before fully tightening. Getting this right matters because improper installation leads to warped parts, failed seals, and eventually expensive water damage problems down the road.

After installing a bathroom faucet, it's really important to run through a thorough 15 minute checkup to avoid costly water damage down the road and make sure everything meets building codes. Start by doing a pressure test on its own. Turn off all the valves first, then pump up the water pressure in the lines to about 0.8 MPa or roughly 116 PSI. Let it sit like that for around ten minutes while keeping an eye on those pressure gauges. If the pressure drops more than 5% during this time, that usually means there's a leak somewhere in the system. Once that's done, move on to looking at things visually and listening carefully too. Check every connection point for signs of moisture or dripping, and listen closely for any strange sounds coming from behind walls or under floors that might indicate hidden problems.

Finally, perform drip-log timing: place a dry paper towel beneath connections and record any drips. If observed, measure intervals between drops—a frequency exceeding one per 90 seconds fails industry standards. This triage method catches 98% of installation flaws before walls are sealed.

Most people can install a bathroom faucet themselves when dealing with basic installations, but there are definitely situations where calling a pro makes sense. For starters, any job that involves changing the structure of things behind the wall or messing with how the countertop was cut out needs someone who knows what they're doing. Plumbers have the right tools and understand all those building codes that regular folks don't think about until it's too late. Then there's the whole mess of fancy features these days. Want a faucet that turns on with just a wave of your hand? Needs a display that shows water temperature? Those require both plumbing skills and electrical know-how to get working safely. And let's face it, nobody wants their bathroom turned into a science experiment. Finally, sometimes when you start taking everything apart, you find problems no one saw coming. Corrosion hiding behind old pipes, valves that won't play nice together, or water damage from years past. Trying to fix these issues without proper training often leads to bigger headaches down the road like cracked pipes or mold growing somewhere it shouldn't. Getting help from professionals isn't just about avoiding leaks it's also about making sure everything meets local regulations so homeowners aren't stuck paying for claims later.

Bathroom faucets are the backbone of high-performance plumbing systems—no amount of design innovation can compensate for subpar installation or compatibility flaws. For B2B/OEM partners targeting global markets, precision-driven installation protocols and product reliability directly impact warranty costs, customer satisfaction, and market competitiveness.

With decades of expertise in plumbing engineering for B2B/OEM applications, we specialize in delivering faucets optimized for seamless installation, global code compliance, and bulk production consistency. Our product line includes ceramic disc valves, thread-compatible fittings, and torque-calibrated components—all backed by strict quality control to minimize post-install failures.

Partner with a trusted OEM supplier rooted in plumbing excellence. Contact us today for a no-obligation consultation, technical specification sharing, or sample testing to align our faucets with your production roadmap. Let’s build reliable, code-compliant bathroom solutions that reduce your warranty risks and drive long-term business growth.